In today’s rapidly evolving manufacturing industry, the maturation of various CNC machining processing technologies has driven higher market demands for product quality.

Within CNC machining, enhancing precision, quality, and efficiency remains a critical objective for enterprise development.

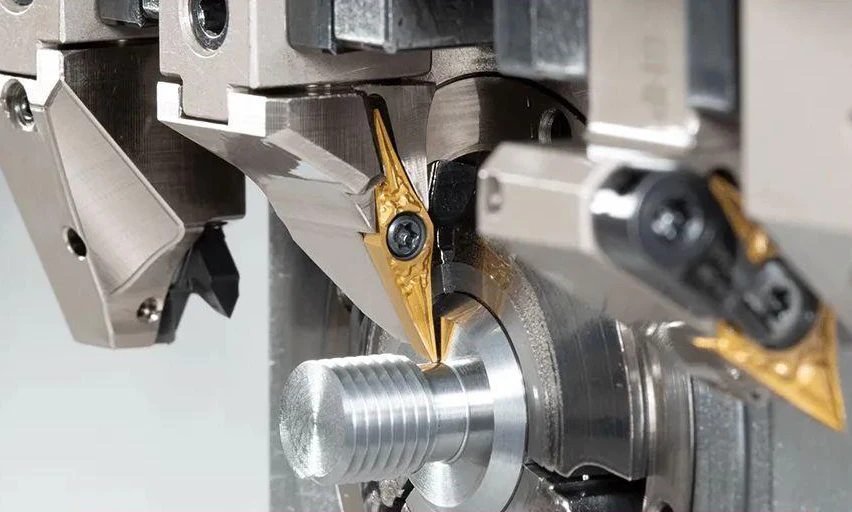

Cutting tools, among the most commonly used machining instruments, directly impact product quality and processing efficiency through their scientific and practical application.

Ensuring their proper utilization is therefore essential.

Common Types of CNC Machine Tool Cutting Tools

Compared to conventional machine tools, CNC machine tools feature faster rotational efficiency, adaptability to diverse machining conditions, and higher levels of intelligent processing control.

These characteristics result in significant differences between the cutting tools used in CNC machine tools and those in conventional machine tools, necessitating tools that meet the operational requirements of CNC equipment.

Generally, CNC cutting tools are categorized based on material properties, structural features, and cutting methods, as shown in Table 1.

Additionally, tool holders for CNC machine tools are primarily categorized into non-indexable tool holders and indexable tool holders based on mounting methods. Indexable tool holders offer superior convenience, stability, and durability.

Among all tools used in mechanical CNC machining, 33.33% employ indexable tool holders, making them the most commonly used type in CNC machining.

Analysis of Factors Affecting Tool Efficiency in CNC Machining

Influence of Rigidity Factors

During mechanical production and processing, the rigidity of cutting tools directly impacts the operational lifespan of the equipment.

When tool rigidity fails to align with actual product machining requirements, prolonged high-speed operation subjects the tools to sustained vibration and friction interference from cutting operations.

This leads to increased susceptibility of machined products to deformation, thereby reducing tool utilization rates and jeopardizing product quality.

Adaptability Factors Interference

During CNC machining operations, tool selection must be carefully tailored to the specific machining tasks of various components.

The cutting, turning, and drilling processes also necessitate different tool applications for CNC machining.

It is widely recognized that CNC production involves diverse product types and highly complex machining programs.

Tools must be selected based on specific production conditions and fundamental requirements, with regular tool changes and maintenance during processing.

However, extending tool life in CNC machining requires alignment with actual production objectives and conditions.

Selected tools must ensure good compatibility and be supported by daily management practices.

Furthermore, in CNC machining operations, well-matched tools reduce replacement frequency.

Should tooling issues arise, appropriately matched tools should be deployed in temporary CNC machining equipment to ensure orderly operation of the CNC machining setup.

Standard Factor Interference

In the new era’s broader context, mechanical CNC machining enterprises have achieved stable development with high levels of automation, intelligence, and informatization.

Component production has completely moved beyond traditional manual processing methods.

Machining techniques can now leverage CNC equipment to enable automated production, supporting high-precision component fabrication.

Consequently, the performance of cutting tools in CNC production processes demands close attention.

Ensuring these tools meet the production requirements of automated CNC machinery is essential for maintaining efficient machining operations and preventing interference with machine tool functions.

Since CNC machining relies on programmed sequences and integrated system management to achieve automated production, comprehensive consideration must be given to tool standardization, service life, and related factors during rapid automated operations.

This approach continuously enhances tool utilization efficiency.

Recommendations for Efficient Tool Utilization in CNC Machining Operations

Controlling Cutting Speed and Feed Rate

To ensure orderly CNC machining operations, operators must effectively manage cutting speed and feed rate.

These parameters should be set according to specific cutting requirements and the fundamental properties of the workpiece.

During CNC machining, controlling cutting speed requires attention to the following factors:

①Material Properties. Generally, hardness and wear resistance directly influence cutting speed.

Excessively high tool hardness increases cutting speed.

② Material Properties. CNC machining centers process diverse components made from varied materials, leading to significant variations in material hardness and cutting frequency.

Controlling cutting frequency requires operators to consider the workpiece’s hardness level and cutting characteristics.

③ Stability Level. During CNC machining, higher cutting speeds can elevate tool vibration susceptibility, potentially causing produced parts to deviate from specifications and increasing tool damage frequency.

CNC machinists must therefore enhance process stability during cutting frequency configuration.

Establishing a Cutting Parameter Database

During CNC machining operations, operators must optimize cutting parameters to ensure full tool utilization and prevent issues such as excessive processing speeds or tool wear on workpieces.

Operators employ scientific management methods to guarantee efficient tool operation.

During tool management system development, R&D personnel must establish a cutting parameter database aligned with corporate production requirements.

Integrating specific product manufacturing standards, they transmit tool material information, subcontracted component material details, feed rates, and spindle speeds to the database system.

Cutting parameters are then configured based on actual technical operation standards and fundamental material properties.

Additionally, during CNC machine tool and cutting tool selection, operators must fully leverage the cutting parameter database to automate control over all tool processing parameters.

This enables immediate access to fundamental information about CNC machine tools and tool attributes, ensuring system-generated parameters align with component production requirements.

Simultaneously, during tool processing, workers develop tool management software and establish a machining parameter database.

This system systematically manages all parameters within the tool database, scientifically categorizing tool geometry data, material properties, and machining characteristics to enhance tool utilization efficiency in CNC machining.

Furthermore, workers integrate the UG system to construct a virtual database.

During CNC machining operations, the team utilizes the UG 3D system to define fundamental tool parameters.

Based on cutting information pushed by the system, they perform rational programming and control of machine tools, adjust tool usage plans, simplify production processes, and ensure smoother overall machining operations.

Regular Tool Evaluation

To control production costs, CNC machining enterprises must ensure processing frequency aligns with actual production requirements while conducting regular tool evaluations.

Leveraging digital technologies, predictive models should be developed to provide critical data support for tool usage.

During CNC machining, the material properties of workpieces, cutting frequency, and cutting depth all influence tool service life.

Therefore, when establishing tool life evaluation models, all relevant influencing factors must be comprehensively considered.

Through experimental operations, predictive models are constructed to obtain critical validation data.

For diverse tool usage parameters (such as cutting duration, cutting force, and wear levels), sensor systems enable automated collection of all data points.

Offline experimental operations yield parameter information under various machining conditions.

Concurrently, workers employ statistical systems and machine learning techniques to construct periodic evaluation models.

Aligned with the enterprise’s component production and machining requirements, regression analysis and neural network technology are applied to analyze core data, thereby establishing a regression model system linking tool service life to cutting parameters.

Optimal Application of New Cutting Tools

Currently, the mechanical CNC machining industry is booming.

In CNC production processes, the development and adoption of new materials have significantly enhanced tool utilization efficiency.

In tool manufacturing, the use of coated materials has effectively optimized performance characteristics.

For instance, current tool research prioritizes PVD coatings.

Tools produced with PVD coatings enhance surface magnetic field strength and increase plasma density, significantly improving tool performance.

This addresses common issues such as adhesion and wear.

Conclusion

In summary, tool consumption is relatively high and costs are significant in CNC machining processes. Improper tool application can adversely affect mechanical production and delay system operation.

To address this challenge, ensuring proper tool usage is essential in CNC machining operations. For instance, tools should maintain excellent surface finish and sharpness during operation.

Relevant parameters must be carefully controlled, and tools should be selected based on specific component machining objectives.

Furthermore, effective tool management practices must be implemented throughout the actual machining process to optimize tool performance, extend tool life cycles, and reduce overall costs.

FAQ

What are the common types of CNC machine tool cutting tools?

CNC machine tools use specialized cutting tools designed for higher rotational efficiency and adaptability. These tools are typically categorized based on material properties, structural features, and cutting methods. Key categories include indexable tool holders, which are widely used for their convenience and durability, making up 33.33% of tools in mechanical CNC machining. Indexable tools are especially preferred due to their stability, reducing tool changes and ensuring better processing efficiency.

How does tool rigidity affect CNC machining efficiency?

Tool rigidity plays a critical role in the efficiency and longevity of CNC machining operations. Low tool rigidity can lead to increased vibrations and friction, which not only reduces tool life but also leads to deformation in the machined products, affecting quality. Proper alignment of tool rigidity with the machining requirements helps prevent tool wear and ensures precise outcomes.

What factors should be considered when selecting tools for CNC machining?

Selecting the right tools for CNC machining requires considering multiple factors such as the material properties of the workpiece, the cutting speed, and the specific machining task (turning, cutting, drilling). Tools must be well-matched to reduce wear and improve productivity. Regular maintenance and the strategic selection of tools help extend tool life and reduce production interruptions.

How can cutting speed and feed rate be optimized in CNC machining?

Optimizing cutting speed and feed rate is essential for efficient CNC machining. Factors like the material's hardness and the workpiece's cutting characteristics must be considered. Higher cutting speeds can improve productivity but may increase tool vibrations. Balancing these parameters is key to preventing damage to the tool and ensuring high-quality machining results.

What is the role of a cutting parameter database in CNC machining?

A cutting parameter database streamlines the CNC machining process by ensuring that the right cutting parameters are applied to each task. By integrating specific product standards and material details, operators can access essential information about tool characteristics, cutting speeds, and feed rates. This helps improve tool utilization, reduce wear, and enhance overall machining efficiency.

How can new cutting tool technologies improve CNC machining?

Advancements in cutting tool technologies, such as the use of PVD coatings, have significantly improved the efficiency and durability of tools in CNC machining. These coatings enhance surface strength and reduce adhesion and wear, leading to longer tool life and better performance. As new materials and coatings are developed, CNC machining continues to evolve, driving higher precision and cost-efficiency.